Nigel Southway is the author of “Take Back Manufacturing,” from which this essay is adapted.

The globalized manufacturing approach, with its efficient supply chains supported by liberalized free-trade agreements, has been the business norm through the last four decades.

It is also the prime reason for the hollowing out of the Western industrial base.

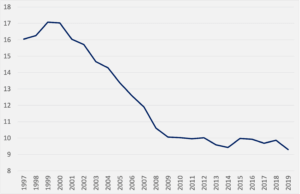

Take Canada. Since 1980, the Canadian manufacturing trade deficit has increased ten times, to more than $100 billion. This significant imbalance in trade has eradicated many jobs and small enterprises, with most of the production-capacity investment and technological development being relocated offshore to foreign factories.

In short, Canada has an economy out of balance. It has an ailing resource sector and a hollowed-out manufacturing base.

Canada’s manufacturing value added (% of GDP)

Source: World Bank

This situation has prompted some political parties to recently ask my advocacy group, the Take Back Manufacturing Forum, what it would take to rebalance our economy by recovering our manufacturing.

It won’t be easy. We did not call our initiative “Welcome Back Manufacturing.” Manufacturing has been neglected, with indifferent industrial policies, under-capitalization, and poor development funding. It’s been outpriced with an over-inflated exchange rate for decades and allowed to be hollowed out by globalization. Don’t expect a fast recovery.

But it’s not impossible. To recover and sustain our Canadian industrial capability, we must have a focused and coordinated road map that is embraced and followed by all involved: our political leadership, our industries, our education system, and our society.

The journey to reshoring must be data-driven, based on a balanced sourcing model that is dynamic and takes into account economic factors like exchange rates, wage rates, and labor productivity.

That road map must follow the three parallel imperatives:

1. New government policies

We continue to struggle to enact industrial policies at the national and provincial levels. Manufacturing things, including leveraging our natural resources as well as our ability to support them with highly functional services, is the only way to achieve a balanced economy to guarantee prosperity.

The federal and provincial governments must work together to improve economic policies to include a definitive industrial policy to rebuild, grow, and sustain the manufacturing base across industrial sectors. These policies must integrate ideas and commitments from leaders, industrialists, and the educational system.

Specifically, on trade, we need to avoid so-called multilateral free-trade agreements that are never followed by the emerging nations, at great expense to the mature nations. Rather, we should form a rigid, localized trade bloc with our US-Mexico-Canada Agreement (USMCA) trade partners to avoid the current high level of imports outside of that trade bloc.

To recover and sustain our Canadian industrial capability, we must have a focused and coordinated road map that is embraced by our political leadership, industries, education system, and society.

2. An integrated industrial learning system for success

We need to reset the Canadian education system’s focus. In coordination with the government, educational institutions should coordinate their efforts with industry to develop an Integrated Industrial Learning System.

Under such a system—which can be applied across trade, technical, administrative, and professional disciplines to support the manufacturing sectors—youth undertake a planned education and training process and gain experience in industry in an integrated manner.

This means there is close coupling of education and practical application. Ultimately, this offers industry a highly certified and licensed workforce, and a shorter deployment cycle to develop the skilled team members needed.

3. Industrial improvements

Local industries must continuously learn and apply productivity improvement concepts.

This includes pursuing lean business strategies, where every part of the business process adds value to the product or customer, while non-value-adding and wasteful steps are eliminated. Further, this requires developing a supply base organized in a close geographical cluster to feed local manufacturing and distribution loops. In addition, businesses need to leverage Industry 4.0 to embrace digital manufacturing innovations and automation to boost productivity.

In conjunction, domestic industries must understand and explore the economics of reshoring options and how to re-install their local supply chains. The journey to reshoring must be data-driven, based on a balanced sourcing model that is dynamic and takes into account various economic factors like exchange rates, wage rates, labor productivity, transportation costs, interest rates, and the like.

Nigel Southway is an independent business consultant and the author of “Cycle Time Management: The Fast Track to Time-Based Productivity Improvement,” a LEAN thinking textbook. He consults and educates worldwide on business productivity improvement, advanced manufacturing engineering, and global sustainability. He is a past chair of the Society of Manufacturing Engineers and the leading advocate for the Take Back Manufacturing Forum. More about the author and the book, “Take Back Manufacturing,” at: www.nigelsouthwayauthor.com