Japan and the US are preparing to announce a new deal to cooperate in cutting-edge chip technology: Tokyo’s Minister of Economy, Trade, and Industry will meet with Commerce Secretary Gina Raimondo on Monday; they are projected to disclose a partnership in developing and producing chips more advanced than two nanometers, as well as in preventing China from accessing sensitive, cutting-edge technologies.

This is a promising move. It suggests that Washington is actively engaging with critical allies to build resilient capabilities in critical industrial inputs. But at the same time, this move is wildly insufficient: It ignores the reality – which today’s semiconductor crisis should make painfully clear – that the upstream matters, is where the US is falling behind, and will be critical to industrial capacity tomorrow.

Washington needs to invest not only in next-generation technological advance, but also into semiconductor production itself, and the materials necessary for it. Such investments are critical for a robust industrial base. They would also be diplomatically advantageous. They would provide the opportunity to extend the bilateral Japan-US agreement into a multilateral one, integrating, for example, other Quad partners like India and Australia.

At a surface level, the United States leads the international semiconductor industry. Intel is the world’s largest semiconductor company by revenue. US companies maintain a near-monopoly in Electronic Design Automation (EDA) software tools, on which leading-edge chip design depends. In 2019, the US claimed a more than 50 percent global market share of integrated circuits, based on total sales.

And yet, the US currently faces what the Commerce Department has called an “alarming” chip shortage – one that has fueled skyrocketing inflation and forced factory shutdowns across the United States.

US innovation means little without production to back it up. One-off, bilateral agreements are of little consequence in an industrial competition defined by scale.

That shortage doesn’t stem from a failure to innovate or a dearth of cutting-edge, flashy technologies. It stems from a dearth of productive capacity: Most US semiconductor fabrication plants are already using some 90 percent of their capacity to manufacture chips. Moving up the value chain, the picture evolves into a more disturbing one of dangerous dependence on untrustworthy external sources for critical inputs. The most frequently used material in semiconductors is silicon. In 2021, China accounted for some 70 percent of global silicon production. After silicon wafers are manufactured in a fab, they proceed to the “back-end” packaging and testing step: Between 2009 and 2020, China’s share of the global packaging and testing market grew from 5 percent to 38 percent.

The US needs to invest, with allies and partners, to shore up these weaknesses; to secure productive capacity all along the semiconductor value chain, including the “dumb” steps and foundational material inputs. And the US is perfectly situated to do this. Congress is currently reconciling House and Senate versions of the Creating Helpful Incentives to Produce Semiconductors (CHIPS) for America Act – a more than 50 billion USD bill to encourage semiconductor manufacturing in the United States. Right now, the bill barely acknowledges the upstream of the semiconductor value chain: It does not mention silicon, and references packaging and testing only in terms of developing advanced capabilities. These tens of billions of dollars should be rethought as an investment in US production – and US production across the entire semiconductor supply chain — not just US technology.

Moreover, the US should expand cooperation with allies and partners that promise complementary capabilities. For example, the US could extend the nascent, bilateral agreement with Japan to include India and Australia, the other two members of the Quad: Australia could contribute its natural resource advantages to shore up supply of critical material inputs; India its capacity for upstream production steps, like packaging and testing.

US innovation means little without production to back it up. One-off, bilateral agreements are of little consequence in an industrial competition defined by scale. The emerging US-Japan semiconductor cooperation agreement is an admirable first step in a new era of multilateral industrial engagement. But the point of a first step is the race that follows.

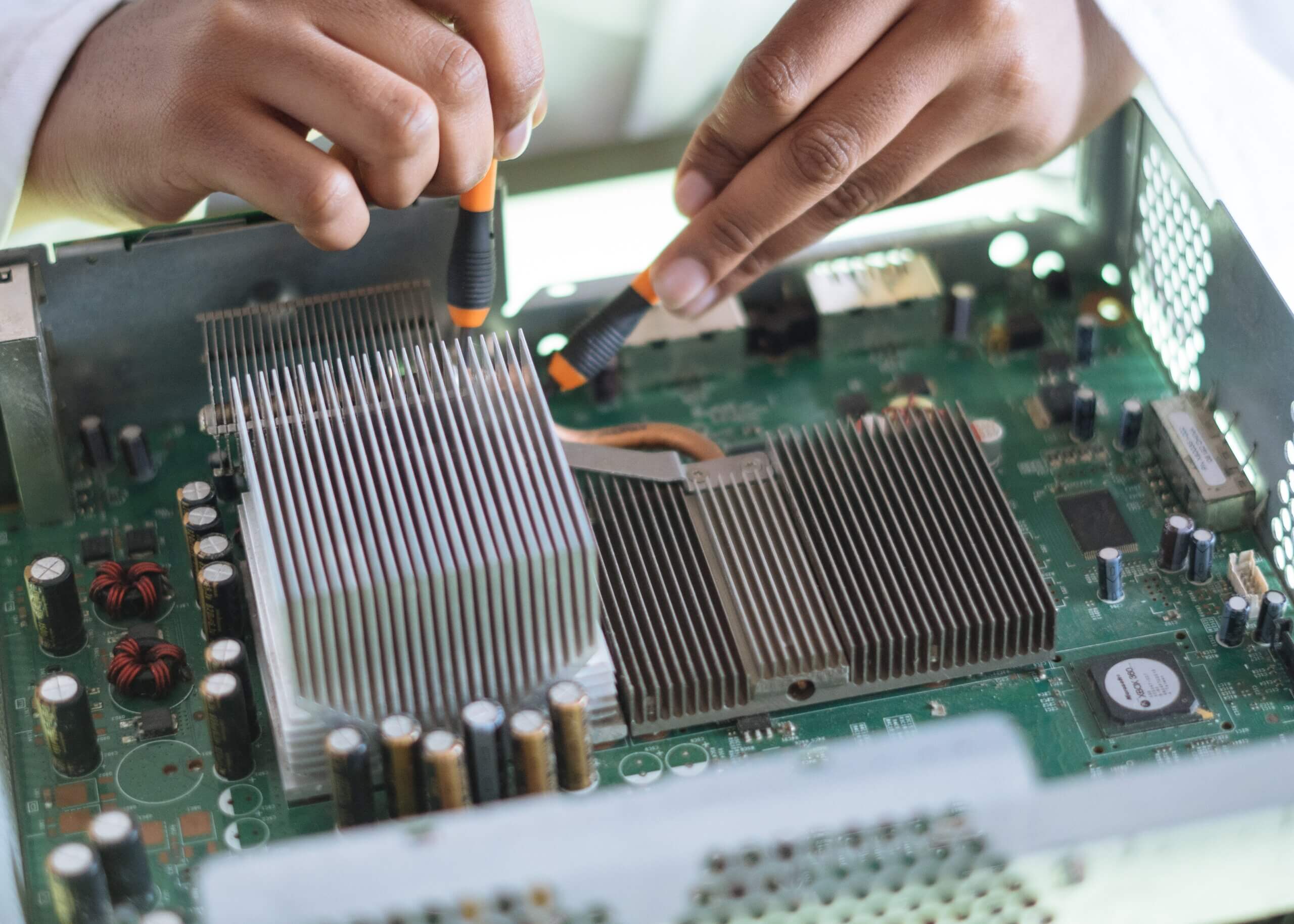

(Photo by Pexels)