Manufacturing jobs in the United States are at their highest in 15 years. At the end of 2023, nearly 13 million people worked in the manufacturing sector, up from 12.8 million pre-pandemic. And the boom is expected to continue as the US reshores production and adds additional capacity. Some 250,000 new manufacturing jobs could be added through 2025, according to one estimate.

Behind booms are factors that risk turning them into busts. Think: pandemics, supply chain concerns, geopolitical flare-ups, and workforce disruptions. How America navigates its current manufacturing boom and leverages it to boost competitiveness and productivity is a central question of our current moment. The right technology can help us figure out the answers.

This is where Auredia enters: our technology uses artificial intelligence and machine learning to ingest large amounts of data. Then, we identify opportunities for optimizing production processes in manufacturing facilities — whether that’s concrete factory floors or carpeted corporate offices.

Humans and machines

First, a brief backstory. Auredia is the brainchild of Ashe Menon, now the senior vice president of global operations at Houston-headquartered oilfield services provider NOV. During the 2014-16 oil prices collapse, driven in large part by a historic boom in US shale oil production, NOV developed the Auredia platform in-house to improve manufacturing operations.

Generally, Auredia’s approach is not new to the industry. A widely accepted standard for measuring manufacturing productivity is what’s called Overall Equipment Effectiveness (OEE). Three elements multiplied together make up OEE: availability (the percentage of time that equipment is in use); performance (the speed at which the equipment is deployed, relative to design speed); and quality (how much is lost due to scrap and rework).

Auredia’s technology helps to amplify manufacturing’s potential output.

Auredia improves on that common calculation to come up with Overall Asset Effectiveness (OAE). Whereas OEE typically focuses on equipment, our OAE calculations put the worker front and center. Our goal is to enable the augmented worker: “man and machine” rather than “man versus machine,” if you will.

Boosting frontline factory workers

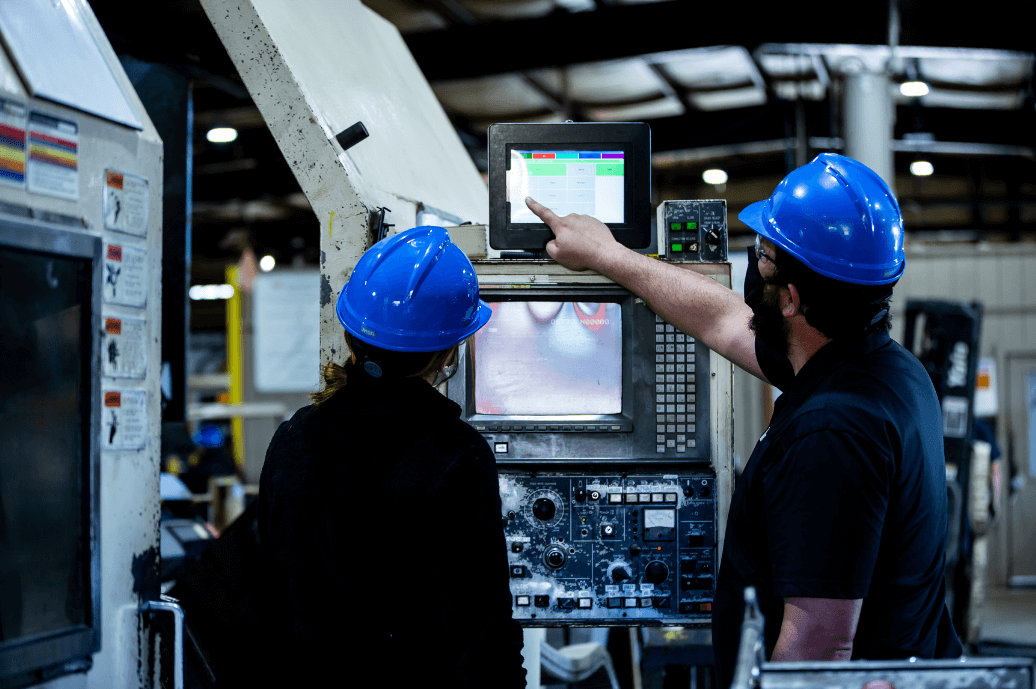

Here’s a glimpse of the augmented worker.

We have developed a heavy-duty tablet for industrial use that can mount to any surface, and that workers can use for real-time data collection. We call this device the human-machine interface. With it, workers can also seamlessly communicate with colleagues on the factory floor and across divisions, enabling them to complete tasks more efficiently. The granular data captured using our devices help workers identify and resolve any operational issues quickly. The data can streamline workflows by presenting clear metrics and prescribing exact next steps to the relevant worker. They also help inform maintenance and tooling optimization.

The software for our human-machine interface devices was developed and honed in one of the largest subtractive manufacturing plants in the US. There, we captured machine data, and correlated it with data shared by our operators. This helps inform operational decisions, like facility upgrades and the costs associated with running a machine, as well as responses to unexpected issues like power outages and inclement weather.

How America navigates its current manufacturing boom and leverages it to boost competitiveness and productivity is a central question of our current moment. The right technology can help us figure out the answers.

Plus, while we connect our human-machine interface devices to different facilities, all data captured ultimately belong to the companies running the manufacturing operations. This means businesses can fully own and engage with their data to best serve their stakeholders and employees.

As we’ve scaled, we’ve brought Auredia to more manufacturing plants around the country – in turn helping us tweak and improve the human-machine interface device controls through feedback from frontline factory workers.

Auredia’s technology helps to amplify manufacturing’s potential output. Our software identifies new opportunities for growth, reduction in costs, and ways to gain competitive advantages. That means greater productivity, profitability, and engagement with the factory floor workers without whom we would not have an American industrial base. Empowering the people who power machines – it’s what we do.

– Amanda Field is the strategic business development manager at Auredia.

(Photo courtesy of Auredia)